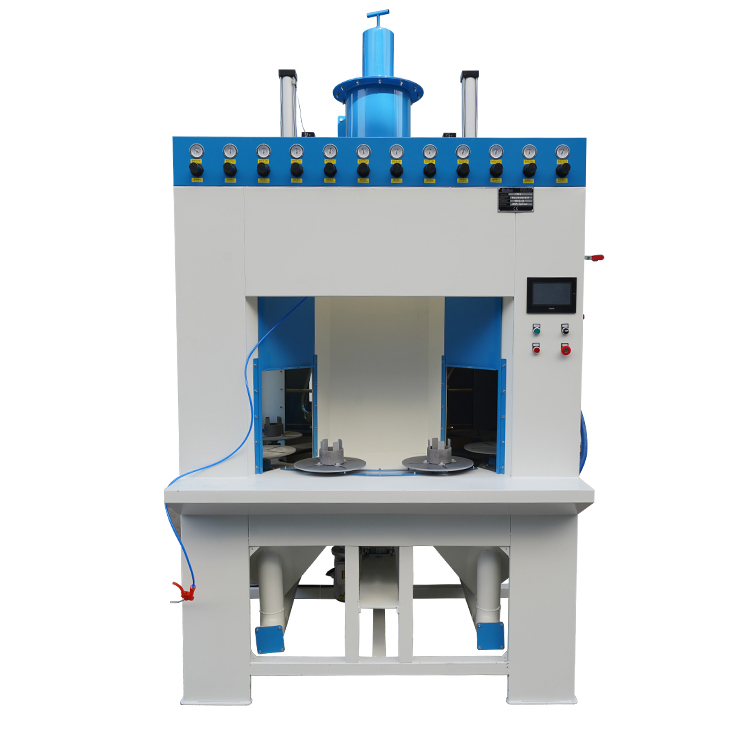

Rotary Indexing Blast Machine, Automatic Sandblasting Machine

This rotary indexing type automatic sandblasting machine is specially designed for batch finishing of inner and outer surfaces of round disc, cylinder or polygon shaped product in high volume production with consistent finishing quality.

Rotary Indexing Blast Machine, Automatic Sandblasting Machine

This rotary indexing automatic sandblasting machine activates through a large indexing turntable taking a quantity of small turntables, blast working under a group of automatic guns. Thanks for the multi independent working station, It is ideal for batch production of pan, pot, cylinders and polygonal shaped parts with uniform and complete finishing.

Rotary Indexing Automatic Sandblasting Machine Applications

-副本-副本.jpg)

Rotary Indexing Automatic Sandblasting Machine Configurations

Each blast gun is individually controlled for woking or not, as well as allows adjustable swinging speed and angle. The blast gun group can be set for fixed blasting or oscillating blasting, which depends on the shaped of the being finished objects.

There are several small turntables evenly placed on the indexing rotary table, each small turntable is a working station loading with workparts, all drives through independent motors, stepless speed regulation by converter. The fixture could be customized according to the shape of workparts.

PLC Touching Screen

PLC Touching ScreenOur automatic blasting system standardly applies advanced PLC electric control system, with a high degree of flexibility and stability. The touching screen offers user-friendly interface to manage the blast gun working, adjust turntable rotates or start the dust collector, etc

Designed with cyclone separator for effectively separation of abrasives from dusts. along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation. It combines with a group of high precison cartridge filters made of 100% polyester.

Rotary Indexing Blast Machine, Automatic Sandblasting Machine Working Process

After operators clip the workparts in the small turntables, the large indexing rotary table drives them precisely to the blasting station where a group of automatic guns working, simultaneously small turntables rotate themselves, ensures abrasive flows cover all the surfaces. After sandblasting, they will be driven to the air blowing station for cleaning, finally rotate to the loading & unloading section.

When production requires blasting parts to an exact quality or design standard, production supervisors can be assured of every part on every shift being blasted in exactly the same way with a rotary indexing automatic blasting system..

Rotary Indexing Blast Machine Specifications (KF-1719-12A for Reference)

*Each of Kafan automatic blasting system can be custom-designed as requests.

| Model | KF-1719-12A |

| Working Chamber Size | L1700 * W1900 * H2350mm |

| Large Turntable Diameter | Dia1400mm * Thick15mm |

| Max. Size of Workparts Allowed | Dia350mm * Height450mm |

| Total Power | 7kw |

| Qty of Small Turntables | 12pcs |

| Automatic Blast Gun | 8pcs, with Boron Carbide Nozzle |

| Control System | PLC |

| Compressed Air Requirement | 3-8bar(kg/cm2) |

| Body Material | Cold Rolled Steel Plates Welded with Painted Surface |

-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)