-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Multi-Station Wet Blast Cabinet, Big Sandblasting Cabinet

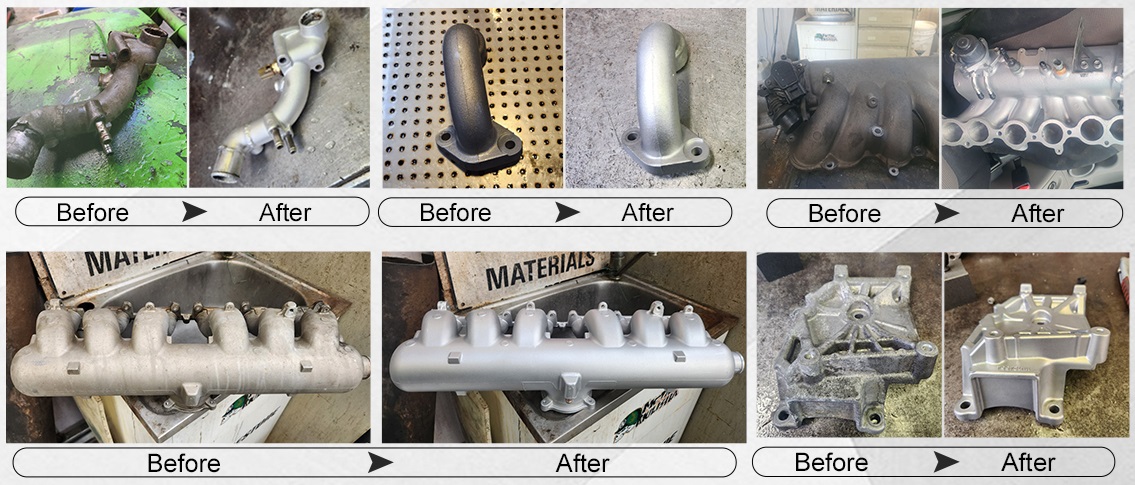

Wet blasting, also known as vapor blasting or water sandblasting, is the initial choice for applications requiring the highest quality of surface finish.

Multi-Station Wet Blast Cabinet, Big Sandblasting Cabinet

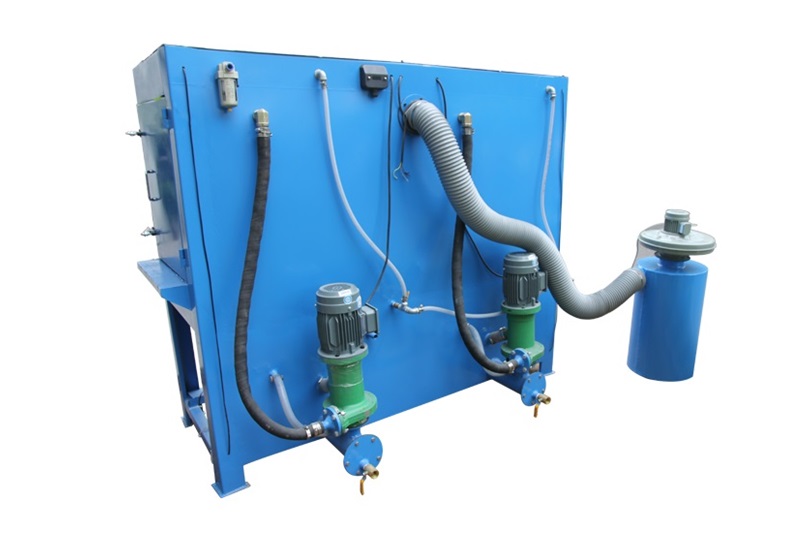

These sandblasting cabinets are designed with 2 working stations allow one or two users to operate together for oversized workpieces, while the big internal space offering your great flexbility. The working size of each blast cabinet can be customized based on product specifications.

Wet blast cabinet works by using a specially pump that agitates water and media into a slurry mixture and delivers it to the blast nozzle, while compressed air is introduced to accelerate the slurry and creates the cleaning effect. Wet blasting meets high requirement finishing standards, resulting in much nicer surfaces.

kafan Wet Blast Cabinet, Manual Sandblasting Machine Features

The Kafan factory-direct manufactured wet blasting machine applies high performance components, longlife materials. professional structure designs, offering reliable, effortless and safe jobs for various surface finishing applications

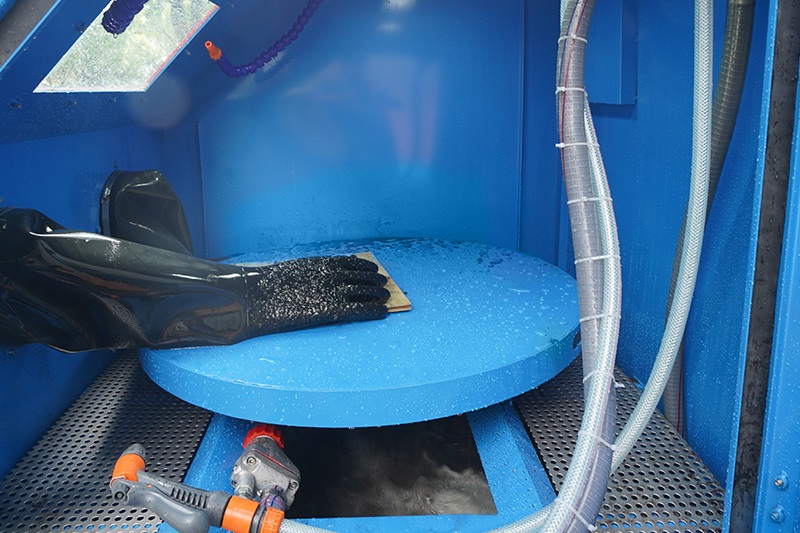

![wet blasting cabin]() The machine body is made 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.

The machine body is made 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.Durable wet blast gun with 8mm boron carbide nozzles specially for high flow wet blasting process,

Configured with windscreen washer maintains visibility throughout the working chamber

The high performance slurry pump fully agitate the abrasive and water.

A demister at the rear of the machine for better view of blasting process.

Blast gun can be easily controlled by foot switch, safe and convenient.

kafan Wet Blast Cabinet Optional Configurations

wet blast cabinet with turntable

wet blast cabinet with turntable

Can be optionally configured with a turntable and track, which faciliate handling heavy objects, reduce operator's efforts. wet blast cabinet with water recirculating

wet blast cabinet with water recirculating

Can be optionally configured with a water recirculating system, used water will be filtered, thus requires no running water.

Why Choose Wet Blasting Cabinet for Surface Preparation

1. Much Cleaner Process. Thanks for the introduce of water, it is not only a finishing process but a washing action, three is no media impregnation into the parts, and not residual dusts on the objects and create a dustfree working chamber.

2. Finer Finish: Water-borne abrasive cushions the impact onto objects during finishing process, giving a finer and higher quality finish, especially for delicate or precise products, such as auto parts(wheels, valvaes, brake calipers).

3. Reduce Wear. The broken rate of media is decreased due to the cushioning from the water, and the blasting tool also gets less wear, as a results that wet blasting reduces production cost.

Double-station Wet Blasting Cabinet Specifications (KF-1212W for Reference)

| Model | KF-1610W |

| Working Chamber Dimension | Length1600 * Width1000 * Height800mm |

| Overall Dimension | Length1700 * Width1500 * Height2000mm |

| Power Supply | 220V/380V, 50-60HZ (voltage can be customized as local) |

| Pump Motor | 3kw |

| Wet Blast Gun | 2pcs, with Boron Carbide Nozzle |

| Light | 18w energy-saving lamps |

| Compressed Air Requirement | 0.4-0.8Mbar |

| Air Flow | 0.5-1.1m3/min |

| Volume of abrasive & water | 150L |

| Feed abrasive | 4-6kgs |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Abrasive:Water | 1:3 |

| Body Material | 3mm Stainless Steel Plates Welded with Coated Surface |

:

Wet Blasting Cabinet Standard Models

| Model |

KF-1610W (double guns) |

KF-1212W | KF-1010W | KF-9080W | KF-7070W |

|

Working Cabinet (L*W*H) |

1600*1000*800mm | 1200*1200*800mm | 1000*1000*800mm | 900*900*800mm | 700*700*800mm |

| Loading Capacity | 100-140kgs | 80-120kgs | 50-80kgs | 30-50kgs | 20-30kgs |

Other Sizes You Need Pls Contact Us for Customization

-副本.jpg?x-oss-process=image/resize)

The machine body is made 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.

The machine body is made 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.

-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)