.jpg?x-oss-process=image/resize,w_100/quality,q_100)

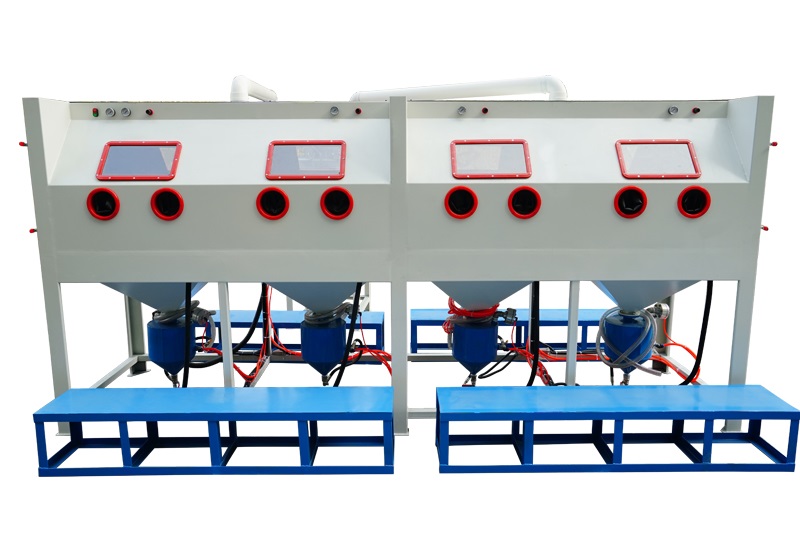

Multi-Station Pressure Blast Cabinet, Large Sandblasting Machine

The Multi-Station Pressure Blast Cabinet can be designed with 2, 3 or 4 working stations for operating oversized sized workparts. Pressure type blast cabinet delivers greater impact intensity for high cleaning efficiency.

Multi-station Pressure Blast Cabinet, Large Sandblasting Machine

Pressure blast cabinets works through a pressurized pot that pushes and accelerates the media to target surfaces. As the medias are delivered at a much higher velocity that causing poweful impact force, pressure blast cabinet is ideal for cleaning heavy unwanted layers, and efficient to handle large surfaces.

Kafan offers design service for pressure blast cabinet with various working stations to operate oversized workparts and suit your specific needs.

Kafan Pressure Blast Cabinet Features

The Kafan factory-direct manufactured pressure blasting machine applies high performance components, longlife materials. professional structure designs, offering reliable, effortless and safe jobs for various surface finishing applications

Well-sealed enclosed cabin design without dust and abrasive leakage features evironmental-friendly.

Each blast cabinet is fitted with a durable blasting gun with boron carbide nozzle for long lasting use.

Configured with an air blowing gun to remove residual dust after blasting.

The high performance pressurized pot powerfully delivers abrasive flow.

Blasting can be controlled by foot padel switch, in order to increase safety and reduce efforts.

![cartridge filter dust collector]() Filter cartridge dust collector removes dust away from the blasting chamber for the operator's visibility

Filter cartridge dust collector removes dust away from the blasting chamber for the operator's visibility

Pressure Blast Cabinet Can be Customized As Requests

Dual-station Pressure Blast Cabinet

Dual-station Pressure Blast Cabinet Four-station Pressure Blast Cabinet

Four-station Pressure Blast Cabinet Large Pressure Blast Cabinet

Large Pressure Blast Cabinet

Why Choose Pressure Blasting Cabinet for Surface Treatment

Compare with suction blast cabinets, pressure type blaster has obvious advantages:

1.With less efforts for removing heavy conteminants and unwanted layers.

2. Job is completed 3 times faster than siphon time, greatly increase the productivity especially for preparig large surfaces.

3. Allows the use of heavy media or large mesh sizes like steel balls for hard materials, such as alloy wheels, marbles, castings

Three-station Pressure Blast Cabinet Specifications (KF-2810P-3 for Reference)

| Model | KF-2810P-3 |

| Working Chamber Dimension | Length2800 * Width1000 * Height750mm |

| Dust Collector Dimension | Length430 * Width430 * Height1600mm |

| Pressure pot | Diameter350mm x Height450mm, 3 pcs |

| Power Supply | 220V/380V, 50-60HZ (voltage can be customized as local) |

| Dust Collector Motor | 1.5kw |

| Blast Gun | 3pcs, with Boron Carbide Nozzle (10mm) |

| Compressed Air Requirement | 5-8bar |

| Body Material | 2.0mm Cold-rolled Steel Plate Welded with Coated Surface |

.jpg?x-oss-process=image/resize)

Filter cartridge dust collector removes dust away from the blasting chamber for the operator's visibility

Filter cartridge dust collector removes dust away from the blasting chamber for the operator's visibility

-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)