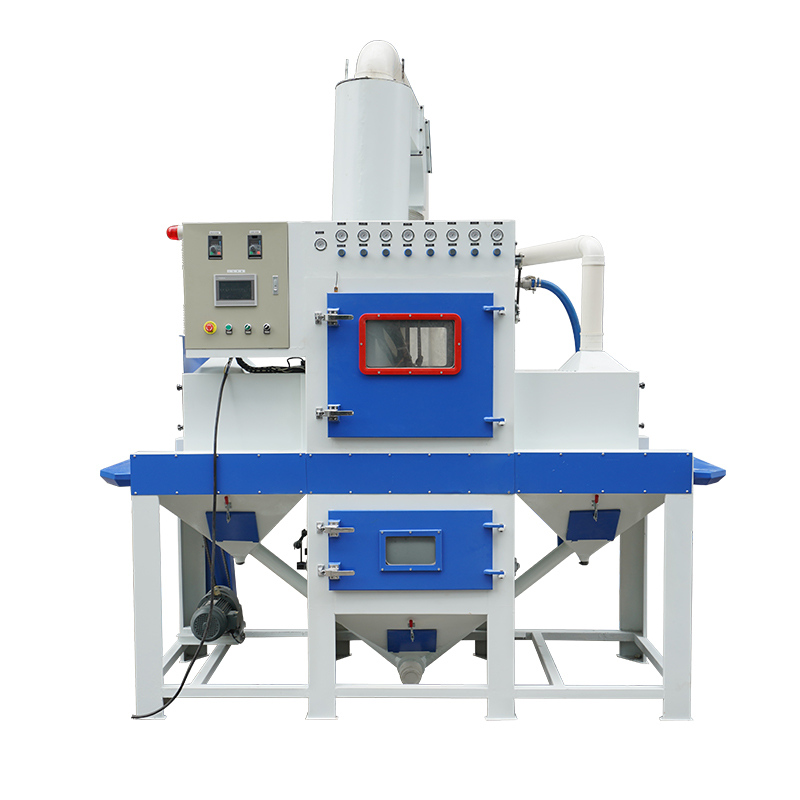

Roller Conveyor Sand Blasting Machine for Double Surfaces Cleaning

The automatic sand blaster allows workparts' double sided faces or all dimentional surfaces to be cleaned with upper blast gun group and lower blast gun group, thus it reduces manual labor to turn over the workparts and greatly increases processing efficiency.

Roller Conveyor Sand Blasting Machine for Double Surfaces Cleaning

The roller conveyor sand blasting machine configured with upper and lower 2 blasting stations, allows the 2 groups of blasting guns cleaning surfaces from upper and bottom sides, which is deal for panels, tubes or profile shaped workparts whose multi-dimensional surfaces need to be cleaned.

The Kafan conveyorized blasting system is a pass-through systems with an array of pre-positioned automatic guns sweeping parts in linear motion synchronized with continuous movement of the belt, which realizes a required big output with uniform quality.

![automatic blasting guns]() Upper Blast Guns

Upper Blast Guns![automatic blasting guns]() Lower Blast Guns

Lower Blast GunsApplication for Rust Steel Plate

Each blast gun is individually controlled for woking or not, as well as allows adjustable swinging speed and angle. The blast gun group can be set for fixing blasting or oscillating blasting, which depends on the shaped of the being finished objects.

The heavy-duty roller conveyor is controlled by frequency converter, and the conveyor speed can be steplessly regulated by the inverter within the range of 1 ~ 5m / min. The actual speed is set depending on process requirements of workpieces.

PLC Touching Screen

PLC Touching ScreenOur automatic blasting system standardly applies advanced PLC electric control system, with a high degree of flexibility and stability. The touching screen offers user-friendly interface to manage the blast gun working, adjust conveyor speed or start the dust collector, etc

Designed with cyclone separator for effectively separation of abrasives from dusts. along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation. It combines with a group of high precison cartridge filters made of 100% polyester.

Belt Conveyor Automatic Sandblasting Machine Working Process

During operation, the operators put the workparts on the conveyor belt, when the workparts are transported into the sandblasting area, they will be abrasive blasted by a group of automatical guns in fixed or oscillating motion, which ensures parts' surfaces are completely cleaned. When the workparts come out from the sandblasting area from the other side of the conveyor, they will be manually or automatically cleaned to remove residual dusts by air guns, and finally discharged.

Belt Conveyor Automatic Sand Blasting Machine Specifications (KF-3810-12A for Reference)

*Each of Kafan automatic blasting system can be custom-designed as requests.

| Model | KF-3810-12A |

| Working Chamber Size | L1100 * W1400 * H1000mm |

| Pass Thru Size | W1000 * H350mm |

| Overall Size | L3800 * W1400 * H2139mm |

| Total Power | 7.8kw |

| Dust Collector Fan Motor Power | 7.5kw |

| Conveyor Belt | 0-5m/min speed adjustable, 0.4kw |

| Automatic Blast Gun | 12pcs, with Boron Carbide Nozzle |

| Control System | PLC |

| Compressed Air Requirement | 3-8bar(kg/cm2) |

| Body Material | Cold Rolled Steel Plates Welded with Painted Surface |

Belt Conveyor Automatic Sand Blasting Machine Standard Models for Choice

| Model No | KF -2706-8A | KF-3208-10A | KF-3810-12A | KF -4615-16A |

|

Working Space (L*W*H)mm |

900*1000*922 | 1100*1200*1000 | 1100*1400*1000 | 1500*1900*1000 |

|

Through size (W*H)mm |

600*300 | 800*300 | 1000*350 | 1500*350 |

| Overall Size (L*W*H)mm |

2700*1000*2059 | 3200*1200*2139 | 3800*1400*2139 | 4600*1900*2139 |

|

Dust collector size (L*W*H)mm |

800*800*2000 | 1200*1300*2400 | 1200*1300*2400 | 1200*1300*2400 |

| Gun quantity | 8pcs | 10pcs | 12pcs | 16pcs |

(1).jpg)

Upper Blast Guns

Upper Blast Guns Lower Blast Guns

Lower Blast Guns